100% rPET for a sustainable future

Coca-Cola HBC Ploiesti plant is the second largest plant in the Group, a center of excellence in innovation and environmental sustainability, with pioneering technologies in Europe. We produce here 70% of the total volumes sold in Romania and export to another 15 countries in the region.

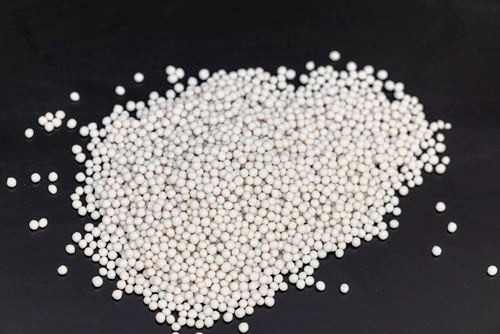

Following a green investment of approximately RON 55 million, we have installed here a state-of-the-art decontamination technology for processing recycled plastic, an important step forward in Coca-Cola HBC's long-term sustainability strategy. This investment opens up the opportunity to have 100% of our portfolio bottled in rPET produced in-house, as the rPET production facility is capable of transforming up to 20,000 tons of PET per year into new bottles, excluding the label and cap, made of 100% recycled PET (rPET). In terms of environmental impact, completing the transition of the PET portfolio to 100% rPET reflects in a significant drop in carbon emissions. The rPET flakes have an 80% lower carbon footprint than virgin PET resin and the rPET production unit uses 100% electricity from renewable sources, meaning no emissions generated.